Temperature drop across inactive cooling coil

Objective/Method/Outcome

Objective: Determines if the cooling coil is leaking

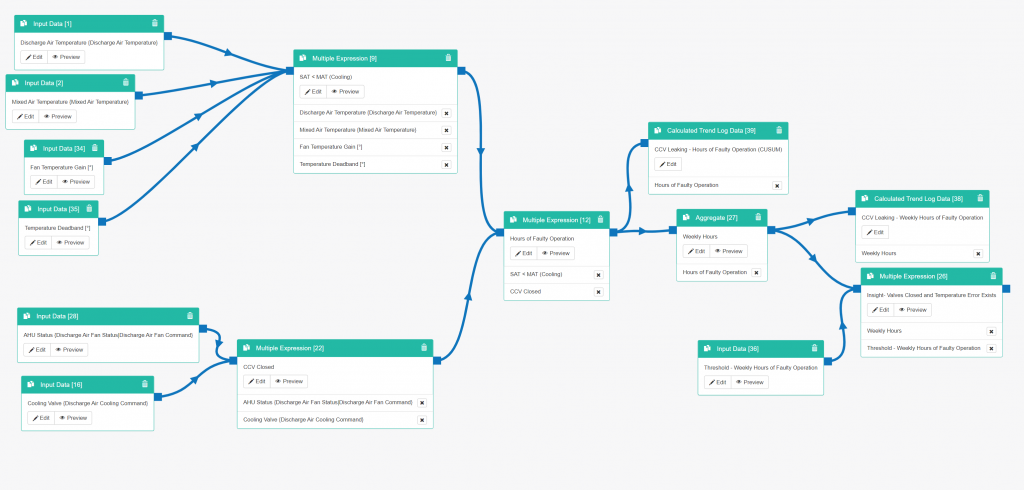

Method: Determines if the supply air temperature is below mixed air temperature by checking if the sum of DAT and temperature deadband is less than the sum of mixed air temperature and fan temperature gain when the cooling valve is closed, and AHU is operational. If this is true, the hours of faulty operation are calculated.

Outcome: Triggers an insight if the hours of weekly faulty operation exceed the acceptable weekly threshold.

Description

Determine if the CCV is likely to be leaking. Check if the SAT is below the MAT when the CCV is closed.

This rule is part of the CopperTree Standard ruleset and is derived from NIST APAR7.

Default Priority

Medium

Diagnosis

- Input sensor(s) faulty or miscalibration. Verify input sensor(s) operation.

- Cooling coil valve stuck and/or leaking. Verify valve/actuator operation.

Message

Cooling coil valve may be leaking.

Rule Template

Insight Type: Fault Detection

Trigger Type: Active High

Logic

Inputs

| Input | Unit | Tags | Description |

|---|---|---|---|

| Discharge Air Temperature | Discharge Air Temperature | The recorded Discharge Air Temperature | |

| Cooling Valve | Discharge Air Cooling Command | The cooling valve status | |

| Mixed Air Temperature | Mixed Air Temperature Discharge Air Fan Status, Discharge Air Fan Command | The recorded mixed air temperature | |

| AHU Status | The status of AHU | ||

| Fan Temperature Gain | ° | ||

| Temperature Deadband | ° | ||

| Threshold – Weekly Hours of Faulty Operation | The minimum hours of faulty operation that can trigger an insight |

Notes

Default Values:

- Fan Temperature Gain: 1.1°

- Temperature Deadband: 2°

- Threshold – Hours of Faulty Operation: 4