Enhanced Prioritization – Primary Air System Runtime Analysis

Objective/Method/Outcome

Objective: Determines if systems are being run outside scheduled hours.

Method: The Supply Fan Status, Return Fan Status, Cooling Valve Command are used to determine if it is operational outside equipment schedule. The daily Avoidable Cost is determined subtracting the actual cost and the scheduled cost and used to project potential savings.

Outcome: Triggers an insight, and calculates Potential Savings.

Description

Monitors runtime outside scheduled hours to calculate Potential Savings from excess energy consumption. This includes supply and return fan electrical consumption, cooling energy consumption, and heating energy consumption. Rule also generates meters for each of these to be used in the “Energy” view.

This rule is part of the CopperTree Standard ruleset.

Default Priority

Medium

Rule Template

Insight Type: Fault Detection

Trigger Type: Active High

Diagnosis

- Schedule or control outputs in manual override, at the BAS front-end or control device.

- Control program error. Verify equipment scheduling and sequence of operations.

Message

Primary air system has been operating outside scheduled hours. Verify equipment scheduling and sequence of operations.

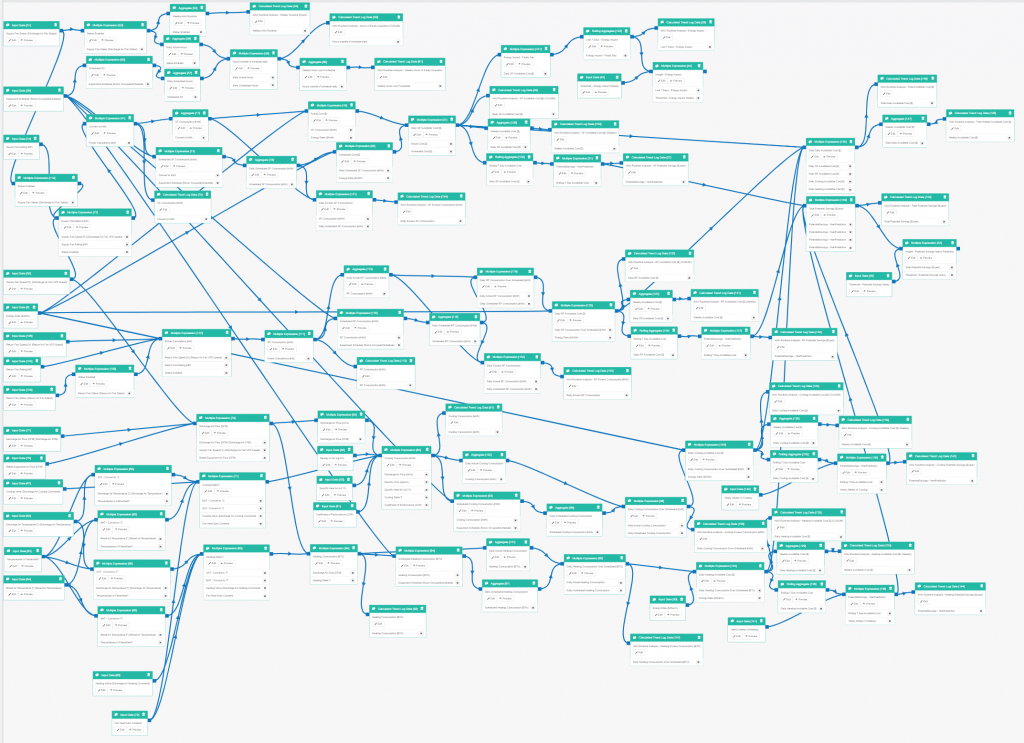

Logic

Inputs

| Input | Unit | Tags | Description |

|---|---|---|---|

| Return Fan Rating | HP | The Return Fan Rating | |

| Return Fan Speed | % | Return Air Fan VFD Speed | The recorded return fan speed |

| Return Fan Status | Return Air Fan Status | The recorded return fan status | |

| Yearly Weeks of Cooling | The annual weeks of cooling | ||

| Yearly Weeks of Heating | The annual weeks of heating | ||

| Threshold – Potential Savings Yearly | The minimum projected potential savings that can trigger an insight | ||

| Equipment Schedule | Room Occupied, Schedule | The scheduled hours of operation for the system | |

| Threshold – Energy Impact Weekly | The minimum energy impact that can trigger an insight | ||

| Supply Fan Speed | % | Discharge Air Fan VFD Speed | The recorded speed of the supply fan |

| Supply Fan Status | Discharge Air Fan Status | The recorded status of the supply fan | |

| Discharge Air Temperature | ° | Discharge Air Temperature | The recorded discharge air temperature |

| Temperatures in Fahrenheit? | This input verifies if the temperature is in Fahrenheit. | ||

| Mixed Air Temperature | ° | Mixed Air Temperature | The recorded mixed air temperature |

| Heating Valve | Discharge Air Heating Command | The status of the heating valve | |

| Cooling Valve | Discharge Air Cooling Command | The status of the cooling valve | |

| Fan Heat Gain Constant | The constant fan heat gain | ||

| Supply Fan Rating | HP | The set supply fan rating | |

| Discharge Air Flow | Discharge Air CFM | The recorded Discharge Air Flow | |

| Rated Equipment Air Flow | |||

| Energy Rate | $/kWh | The rate of energy | |

| Coefficient of Performance | COP | ||

| Density of Air | kg/m3 | The assumed density of air | |

| Specific Heat Air | kJ/°C | The assumed specified heat air | |

| Energy Rate | $/therm | The assumed rate of energy |

Notes

If airflow station is not present, “0” can be entered into the “Discharge Air Flow” input. Fan speed and maximum rated flow will be used to calculate flow.

If an airflow station is present, the “Rated Equipment Air Flow” will be overridden, and the flow sensor will be utilized.

Fahrenheit or Celsius inputs can be toggled with the “Temperatures in Fahrenheit?” input block. Use “1” for Fahrenheit (default), and “0” for Celsius.

Default Values for Constants:

- Supply Fan Rating [HP]: 20HP

- Return Fan Rating [HP]: 15HP

- Yearly Weeks of Cooling: 26

- Yearly Weeks of Heating: 26

- Fan Heat Gain Constant: 1.5°

- Rated Equipment Air Flow [CFM]: 15000

- CFM Energy Rate ($/kWh): $0.10

- Energy Rate ($/therm): $0.30

- Coefficient of Performance (COP): 3

- Density of Air (kg/m3): 1.2

- Specific Heat Air (kJ/°C): 1.2

- Insight Threshold – Potential Savings Yearly [$]: $100