Mixed air temperature control is poor

Objective/Method/Outcome

Objective: Determines if the temperature control of mixed air temperature control is poor.

Method: Compares the recorded temperature of the mixed air temperature and the setpoint and checks if it is greater than the dead band for more than the appropriate amount of time during operational hours.

Outcome: Triggers an Integrity KPI insight.

Description

Determine the error severity of a mixed air temperature control system in degree*hours.

This rule is part of the CopperTree Standard rule-set.

Calculate the severity metric based on the absolute difference between the mixed air temperature (MAT) and the MAT setpoint deadband during scheduled hours.

Default Priority

Medium

Diagnosis

- Issue with control loop. Review and modify controller tuning parameters.

- Automatic setpoint control has been overridden. Revert setpoint back to automatic control.

- Input sensor(s) faulty or miscalibrated. Verify input sensor(s) operation.

Message

Mixed air temperature has deviated from setpoint at a higher severity than specified.

Rule Template

Insight Type: Integrity KPI

Trigger Type: Active High

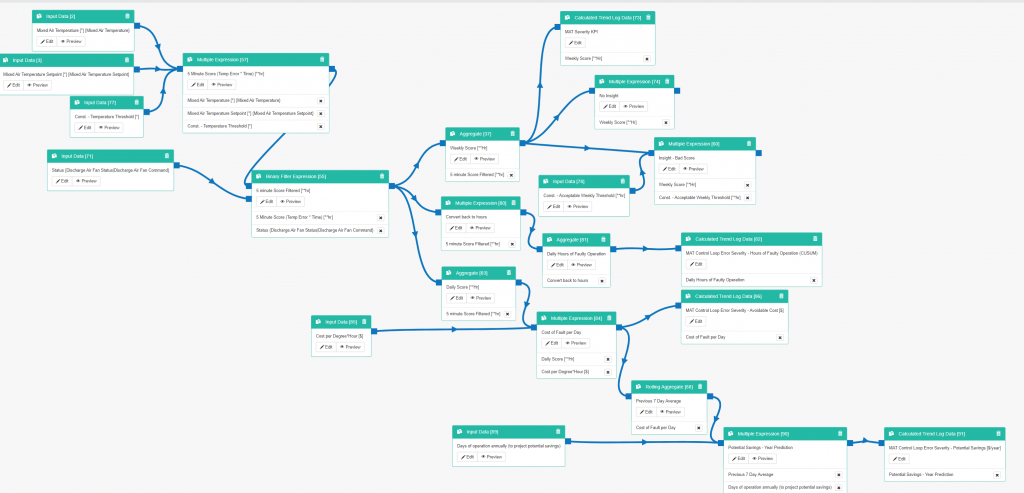

Logic

Inputs

| Input | Unit | Tags | Description |

|---|---|---|---|

| Mixed Air Temperature | ° | Mixed Air Temperature | The recorded MAT |

| Mixed Air Temperature Setpoint | ° | Mixed Air Temperature Setpoint | The preset MAT setpoint |

| Status | Discharge Air Fan Status, Discharge Air Fan Command | The recorded status of DAF | |

| Const. – Temperature Threshold | ° | The minimum temperature that can trigger an insight | |

| Const. – Acceptable Weekly Threshold | °*hr | The acceptable weekly hours of fault | |

| Cost per Degree*Hour | $ | The cost of fault per degree, per hour | |

| Days of operation annually | The yearly days of operation used to project potential savings |

Notes

Default Thresholds:

- Temperature Deadband: 1.5°

- Acceptable Weekly Degree*Hours: 40